LabSuite incorporates a list of different moisture-density test specifications, which consists of:

- The physical requirements of the test, such as the dimensions of the mold, the number of soil layers and blows per layer and the hammer weight and drop.

- Oversize correction requirements such as the size of sieve used to separate out oversize material and the oversize moisture and density correction method.

- Unique reporting requirements, such as whether to report the non-oversize corrected test results as well as the corrected test results.

Each moisture-density test entered into the system must be associated with a test specification from this list.

If two or more computers will be used to access your test data you'll want to make sure that the test specifications you use are available on every computer that accesses the test data. You can do this by making sure that the package's shareable config. files directory is set up to point to the same network directory on each computer. To do this, start your GEOSYSTEM package, then, from the program's opening screen, select Options > Setup General Options, click on Files in the following dialog's left-hand navigation dialog, then fill in the right-hand Report, data entry form and shareable config files path box with a network directory. Do this procedure on every computer, starting with the computer you've been using to enter specification sets. (The software will copy those sets from their current location to the new network share point only if the share folder hasn't been accessed by another computer first.)

To edit the program's test specification database, select Options > Program Setup then click on Calculated Values underneath Moisture-Density in the navigation list at the dialog's left side, then click on the Edit button.

To edit a test specification:

Test specifications currently stored in the database are listed on the left-hand side of the panel: To view or edit a specification in the list, simply click on the specification's name.

To create a new test specification:

You can add a new test specification by clicking on the New button, or you can start with an existing test specification and save it under a new name by clicking on the test specification in the left-hand list, then click on the Copy button.

To remove a test specification from the database:

Click on the test specification's name in the specification list then click on the Delete button.

A moisture-density test specification includes the following information:

Each specification must be associated with a unique name that describes the test method. A typical specification name would be ASTM D698-91, Method A.

Two test specifications may share the same name if different values are entered into the Standard/modified/other field for the two specifications: for example, there may be two ASTM D698-91, Method A test specifications - one Standard, the other Modified.

Oversize material is larger than

For test procedures that require an oversize material correction, this selection specifies the sieve opening size that denotes the oversize material boundary.

Select Proctor test for a normal moisture-density test not involving the California Test Method 216 (CT-216) procedure.

For CT-216 tests, LabSuite supports two test methods: a modified CT-216 test procedure where moisture contents are taken at each test point (this method is labeled as CT-216 with added moisture content tests in the test method selection box), and a by-the-book CT 216 procedure without moisture contents (labeled California Test 216 in the selection box).

This specification requires a unique rounding selection

The software has maximum dry density and optimum moisture content rounding settings (Round max. density to and Round opt. moisture to, covered here) that affect almost every test specification; however, you can choose to override these settings for individual test specifications. This can be useful for setting the test results rounding selection for particular moisture-density test specifications that mandate a specific rounding procedure for test results (e.g., ASTM D698 requires reporting the maximum dry density to 0.1 pcf, while ASTM D1557 requires rounding to 0.5 pcf).

If you would like to require a particular rounding procedure for a given test specification, check the This specification requires a unique rounding selection box, then select the proper rounding option in the Max. density and Opt. moist. boxes.

Max. density

These options control the rounding of the maximum density and optimum moisture content results calculated by the program for a test using the current test specification. The selection boxes are only available if the This specification requires a unique rounding selection box is checked; otherwise, the program rounds the results for tests using the test specification according to the rounding settings chosen here.

Selects the method by which density results from tests using the specification are to be corrected for the presence of oversize material (i.e., rock). Select No oversize density correction if you do not want to correct the calculated densities.

Selects the method by which moisture content results from tests using the specification are to be corrected for the presence of oversize material. Select No oversize moisture correction if you do not want to correct the calculated moisture contents.

- You can stop the program from correcting the moisture and density results for any given test, even if the test's specification requires corrections: Simply do not enter a percentage for the oversize material, or a bulk specific gravity.

LabSuite can apply the density and moisture oversize corrections to each test point or just to the calculated maximum dry density and optimum moisture content.

- The only real difference between the two options is that if the option to apply the corrections to each test point is chosen, you can opt to have the program plot both the corrected and uncorrected curves as part of the hardcopy reports; if the option to apply the corrections only to the final results is chosen, the corrected maximum density/optimum moisture content will be reported, but charts will only include the uncorrected curve.

Report the uncorrected results in addition to the corrected results

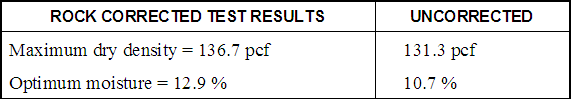

When an oversize correction is applied, the program can be configured to report uncorrected maximum dry density/optimum moisture values in addition to the corrected test results. This selection affects both the data summary report and the chart report. For example, the following figures demonstrate the effect of selecting and unselecting this option on the PRGEOSYS chart report:

Chart Report Test Results Box Showing Corrected Results

Chart Report Test Results Box Showing Corrected and Uncorrected Results

Report the uncorrected curve in addition to the corrected curve

When this option is selected, LabSuite will plot two curves on moisture-density charts: One curve will be plotted using the original, uncorrected, test results, while the second curve will be plotted using the test's density and moisture results after correcting for the presence of oversize material.

- This option will not be available if you select

Only the max. density and opt. moisturein the Correct box because there is no corrected curve: The uncorrected is plotted to calculate an uncorrected maximum density and optimum moisture content, then the oversize correction is applied to the results.

Mold height

For non-CT-216 tests, LabSuite utilizes the mold diameter and height required by the selected test specification to calculate a mold volume that is used during data entry as a default for each compaction point's Mold volume test data entry field.

Hammer drop

Blows per layer

Number layers

These fields are optional. If data are entered for all four prompts, it will be included as part of the test specification listed on chart reports.

- Because LabSuite does not automatically include measurement units as part of the specification listing, make sure to add

lb.orkg.to the hammer weight andin.orcms.to the hammer drop.